GE looks to TI for DCJ cooling system production

January 11, 2013 | 11:02

Companies: #general-electric #texas-instruments

General Electric - the do-everything company with a finger in every pie from consumer electronics to aeronautics - has offered hope to those who have been looking forward to its DCJ cooling technology in the form of a planned production partnership with Texas Instruments.

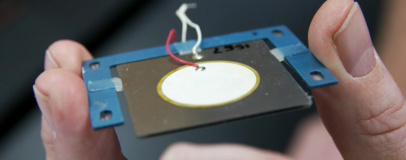

Dual Piezoelectric Cooling Jet technology, to give the system its full name, was first unveiled by the company in December and promises much: creating a teeny-tiny electromechanical bellows system, GE claims that DCJ can replace traditional fans in electronics systems in a fraction of the space - perfect for cramming ever-more-powerful components into increasingly-slim devices like smartphones and tablets.

The prototype system developed by GE measures a scant 4mm thick - around half that of the closest traditional cooling fan. It's not all about size, however: the device also draws less than half the power of a spinning fan, and is inherently more reliable thanks to a reduction in moving parts or bearings that can seize up as a result of dust or moisture.

What GE didn't offer in its impressive presentation on the matter was any plans for a launch. It had a single customer, cooling specialist Fujikura, lined up, but no other plans beyond the offering of demonstration kits to original equipment manufacturers (OEMs) keen to investigate the technology for use in their own products.

Now, the company has stated that it hopes to have the technology in consumer devices by the end of the year thanks to a partnership with semiconductor giant Texas Instruments. Speaking to Engadget at the Consumer Electronics Show in Las Vegas, a GE representative explained that the two companies were looking to partner on the technology, with GE providing the know-how and TI the manufacturing capability. Working together, the system could hit the open market by the end of the year - making it an ideal solution for Intel's Ultrabook project, which is targeting sub-6mm chassis thicknesses that are near-impossible with traditional cooling solutions.

Sadly, while we now have a somewhat firmer timescale for the launch of DCJ-equipped products, we're still missing one vital piece of information: how much more expensive the technology is compared to a slimline cooling fan, and how much of that expense is going to be passed on to the consumer in the form of raised device prices.

Dual Piezoelectric Cooling Jet technology, to give the system its full name, was first unveiled by the company in December and promises much: creating a teeny-tiny electromechanical bellows system, GE claims that DCJ can replace traditional fans in electronics systems in a fraction of the space - perfect for cramming ever-more-powerful components into increasingly-slim devices like smartphones and tablets.

The prototype system developed by GE measures a scant 4mm thick - around half that of the closest traditional cooling fan. It's not all about size, however: the device also draws less than half the power of a spinning fan, and is inherently more reliable thanks to a reduction in moving parts or bearings that can seize up as a result of dust or moisture.

What GE didn't offer in its impressive presentation on the matter was any plans for a launch. It had a single customer, cooling specialist Fujikura, lined up, but no other plans beyond the offering of demonstration kits to original equipment manufacturers (OEMs) keen to investigate the technology for use in their own products.

Now, the company has stated that it hopes to have the technology in consumer devices by the end of the year thanks to a partnership with semiconductor giant Texas Instruments. Speaking to Engadget at the Consumer Electronics Show in Las Vegas, a GE representative explained that the two companies were looking to partner on the technology, with GE providing the know-how and TI the manufacturing capability. Working together, the system could hit the open market by the end of the year - making it an ideal solution for Intel's Ultrabook project, which is targeting sub-6mm chassis thicknesses that are near-impossible with traditional cooling solutions.

Sadly, while we now have a somewhat firmer timescale for the launch of DCJ-equipped products, we're still missing one vital piece of information: how much more expensive the technology is compared to a slimline cooling fan, and how much of that expense is going to be passed on to the consumer in the form of raised device prices.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.