Researchers unveil polymer-based TIM

April 1, 2014 | 09:08

Companies: #georgia-institute-of-technology #researchers

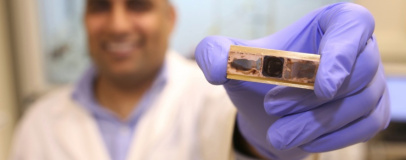

Researchers at the Georgia Institute of Technology have announced what they claim is a novel way of improving the transfer of heat from computer chips to heatsinks: a polymer-based thermal interface material (TIM) which can be applied in a layer just three microns thick.

Polymers may not be the obvious choice when it comes to conducting heat or electricity, but the team has developed a method which aligns the polymer chains themselves in nanofibres - avoiding problems with the previous technique of forming aligned crystalline structures which are too brittle to be of use. Using polythiophene, the team has been able to modify the polymer's structure in such a way to boost the thermal conductivity 20-fold and yet have the new material operate reliably at temperatures of up to 200 degrees Celsius.

'Thermal management schemes can get more complicated as devices get smaller,' explained Baratunde Cola, assistant professor of mechanical engineering at the Georgia Institute of Technology. 'A material like this, which could also offer higher reliability, could be attractive for addressing thermal management issues. This material could ultimately allow us to design electronic systems in different ways.'

The team's initial target market is high-temperature devices which can't use solder as the thermal interface material. Commonly used to connect large heatspreaders to the far smaller die on processors, solder proves problematical when the temperature of the device begins to approach that required to turn the solder molten once more. 'Polymers aren’t typically thought of for these applications because they normally degrade at such a low temperature,' Cola explained. 'But these conjugated polymers are already used in solar cells and electronic devices, and can also work as thermal materials. We are taking advantage of the fact that they have a higher thermal stability because the bonding is stronger than in typical polymers.'

Another advantage of the new material is that it can be applied in a layer just three microns thick while still maintaining its performance, compared with the usual 50 to 75 micron layer required of traditional thermal interface materials. The thinner the layer, the closer the heatsink can be positioned to the chip being cooled - and the more efficient the heat transfer. Stresses normally associated with thermal cycling - constant heating and cooling cycles, common to semiconductors as they are loaded and unloaded - are also avoided, Cola claims.

While Cola has already applied for a patent on the technique and formed a start-up company, Carbice Nanotechnologies, for its commercialisation, it could be a while before it's product-ready: Cola admits that the theoretical processes behind the manufacturing are not yet fully understood, and the technique itself requires further development to improve yields.

The team's work is published in the latest Nature journal, under the title 'High thermal conductivity of chain-oriented amorphous polythiophene.'

Polymers may not be the obvious choice when it comes to conducting heat or electricity, but the team has developed a method which aligns the polymer chains themselves in nanofibres - avoiding problems with the previous technique of forming aligned crystalline structures which are too brittle to be of use. Using polythiophene, the team has been able to modify the polymer's structure in such a way to boost the thermal conductivity 20-fold and yet have the new material operate reliably at temperatures of up to 200 degrees Celsius.

'Thermal management schemes can get more complicated as devices get smaller,' explained Baratunde Cola, assistant professor of mechanical engineering at the Georgia Institute of Technology. 'A material like this, which could also offer higher reliability, could be attractive for addressing thermal management issues. This material could ultimately allow us to design electronic systems in different ways.'

The team's initial target market is high-temperature devices which can't use solder as the thermal interface material. Commonly used to connect large heatspreaders to the far smaller die on processors, solder proves problematical when the temperature of the device begins to approach that required to turn the solder molten once more. 'Polymers aren’t typically thought of for these applications because they normally degrade at such a low temperature,' Cola explained. 'But these conjugated polymers are already used in solar cells and electronic devices, and can also work as thermal materials. We are taking advantage of the fact that they have a higher thermal stability because the bonding is stronger than in typical polymers.'

Another advantage of the new material is that it can be applied in a layer just three microns thick while still maintaining its performance, compared with the usual 50 to 75 micron layer required of traditional thermal interface materials. The thinner the layer, the closer the heatsink can be positioned to the chip being cooled - and the more efficient the heat transfer. Stresses normally associated with thermal cycling - constant heating and cooling cycles, common to semiconductors as they are loaded and unloaded - are also avoided, Cola claims.

While Cola has already applied for a patent on the technique and formed a start-up company, Carbice Nanotechnologies, for its commercialisation, it could be a while before it's product-ready: Cola admits that the theoretical processes behind the manufacturing are not yet fully understood, and the technique itself requires further development to improve yields.

The team's work is published in the latest Nature journal, under the title 'High thermal conductivity of chain-oriented amorphous polythiophene.'

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.