Intel has confirmed reports of a chemical leak at its Arizona facility, the result of which has injured 43 people and hospitalised 12 through nitrogen inhalation.

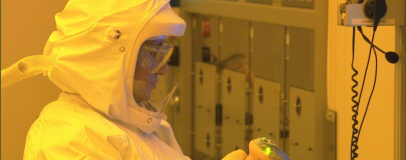

Intel's two campuses in Chandler, Arizona combine to form the company's second-biggest facility in North America. The company has expanded its fabrication operations in Arizona over the years to the point where it employs an impressive 11,000 people and has a third manufacturing plant under construction at the site. The leak is reported to have occurred at Fab 32, which was Intel's first plant to mass-produce chips on a 45nm process node.

Thankfully, the chemical leak - identified by the Arizona fire department as nitrogen trifluoride, a chemical used during the plasma etching process - was spotted before it could build to serious levels. According to local news outlet Arizona Republic the leak occurred at six in the morning on Saturday, local time, and was discovered when an employee complained of breathing difficulties. The emergency services were contacted, and initial reports from Intel indicated that 24 people were treated locally for eye irritation and breathing difficulties while six were taken to hospital for further observation.

Those numbers rose steadily as they day progressed, with the final figure sitting at 43 treatments and 12 hospitalisations - although none of the injuries are reported as being life-threatening.

Intel spokesperson Jason Bagley has stated that the leak appears to have been the result of an O-ring failing in the gas exhaust system that should pipe the used nitrogen trifluoride out of the facility, with the result that the gas was vented into the plant itself. According to Bagley, production is being transferred to another area of the plant while the fault is repaired and output is not thought to be affected. Sadly, Bagley has been less forthcoming on the status of those hospitalised by the incident.

During use in plasma etching, nitrogen trifluoride breaks down into fluorine and nitrogen - the former of which acts as an active etching agent. Fluorine gas, which can be released as a by-product of the etching process, is extremely hazardous: concentrations above 25 parts per million (PPM) are high enough to cause significant irritation to the eyes, respiratory tract, lungs, liver and kidneys, while concentrations above 100PPM cause potentially fatal damage. Thus far, it is not clear whether the leak was of fluorine gas mixed with nitrogen trifluoride, or just nitrogen trifluoride. The latter by itself is much less irritating, but can lead to a potentially serious condition known as methemoglobinemia in high concentrations.

This isn't the first time Intel's Fab 32 has hit the news for employee safety concerns: back in 2011 seven workers were injured in a solvent fire, while later that same year a further eight suffered smoke inhalation when construction work caused a plastics fire.

Intel's two campuses in Chandler, Arizona combine to form the company's second-biggest facility in North America. The company has expanded its fabrication operations in Arizona over the years to the point where it employs an impressive 11,000 people and has a third manufacturing plant under construction at the site. The leak is reported to have occurred at Fab 32, which was Intel's first plant to mass-produce chips on a 45nm process node.

Thankfully, the chemical leak - identified by the Arizona fire department as nitrogen trifluoride, a chemical used during the plasma etching process - was spotted before it could build to serious levels. According to local news outlet Arizona Republic the leak occurred at six in the morning on Saturday, local time, and was discovered when an employee complained of breathing difficulties. The emergency services were contacted, and initial reports from Intel indicated that 24 people were treated locally for eye irritation and breathing difficulties while six were taken to hospital for further observation.

Those numbers rose steadily as they day progressed, with the final figure sitting at 43 treatments and 12 hospitalisations - although none of the injuries are reported as being life-threatening.

Intel spokesperson Jason Bagley has stated that the leak appears to have been the result of an O-ring failing in the gas exhaust system that should pipe the used nitrogen trifluoride out of the facility, with the result that the gas was vented into the plant itself. According to Bagley, production is being transferred to another area of the plant while the fault is repaired and output is not thought to be affected. Sadly, Bagley has been less forthcoming on the status of those hospitalised by the incident.

During use in plasma etching, nitrogen trifluoride breaks down into fluorine and nitrogen - the former of which acts as an active etching agent. Fluorine gas, which can be released as a by-product of the etching process, is extremely hazardous: concentrations above 25 parts per million (PPM) are high enough to cause significant irritation to the eyes, respiratory tract, lungs, liver and kidneys, while concentrations above 100PPM cause potentially fatal damage. Thus far, it is not clear whether the leak was of fluorine gas mixed with nitrogen trifluoride, or just nitrogen trifluoride. The latter by itself is much less irritating, but can lead to a potentially serious condition known as methemoglobinemia in high concentrations.

This isn't the first time Intel's Fab 32 has hit the news for employee safety concerns: back in 2011 seven workers were injured in a solvent fire, while later that same year a further eight suffered smoke inhalation when construction work caused a plastics fire.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.