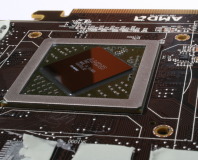

At AMD's Technical Forum and Exhibition 2010, we had a quick chat with Matt Skynner, Corporate VP and General Manager of AMD's GPU Division, about the decision to continue using TSMC's 40nm process for ATI's Radeon HD 6000 series. (We'll continue to refer to AMD's graphics division as ATI until Fusion launches.)

We asked if these new graphics cards launched too early, instead of late this year/next year when TSMC's 28nm process was ready.

Mr Skynner admitted that the HD 6000 series was originally set to use TSMC's 32nm process, but that AMD had to opt back to 40nm earlier this year after that process was unceremoniously dumped by TSMC in favour of concentrating on 28nm only. Excluding the yield issues with the more recent 40nm process, TSMC does have great experience in creating high performance, low power half-node processes suitable for GPUs at 110nm, 80nm and 55nm, and this is where 28nm looks to continue.

TSMC claims to have its 28nm process ready pretty much about now, which gave us ammunition to pressure Skynner over the perceived lack of gap between new Radeon HD 6000 series and future 28nm ATI Radeon parts.

The reply was not to TSMC's credit, and although the answer was not direct there was a strong inference that TSMC's 28nm roadmap has been pushed back towards the middle of next year. Ouch. If entirely dropping 32nm wasn't enough, it appears the problems of high-k, metal gate and EUV lithography are significant for a company that hasn't used them before. The next question is therefore how this affects Nvidia's refresh as well.

Other reasons for an October/November launch for the HD 6000 series included the holiday/Christmas season, which is obviously a ripe time for sales, regardless of industry.

Will TSMC's problems continue to be holding the graphics industry back? Let us know your thoughts in the forums.

We asked if these new graphics cards launched too early, instead of late this year/next year when TSMC's 28nm process was ready.

Mr Skynner admitted that the HD 6000 series was originally set to use TSMC's 32nm process, but that AMD had to opt back to 40nm earlier this year after that process was unceremoniously dumped by TSMC in favour of concentrating on 28nm only. Excluding the yield issues with the more recent 40nm process, TSMC does have great experience in creating high performance, low power half-node processes suitable for GPUs at 110nm, 80nm and 55nm, and this is where 28nm looks to continue.

TSMC claims to have its 28nm process ready pretty much about now, which gave us ammunition to pressure Skynner over the perceived lack of gap between new Radeon HD 6000 series and future 28nm ATI Radeon parts.

The reply was not to TSMC's credit, and although the answer was not direct there was a strong inference that TSMC's 28nm roadmap has been pushed back towards the middle of next year. Ouch. If entirely dropping 32nm wasn't enough, it appears the problems of high-k, metal gate and EUV lithography are significant for a company that hasn't used them before. The next question is therefore how this affects Nvidia's refresh as well.

Other reasons for an October/November launch for the HD 6000 series included the holiday/Christmas season, which is obviously a ripe time for sales, regardless of industry.

Will TSMC's problems continue to be holding the graphics industry back? Let us know your thoughts in the forums.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.