Each module is hand-checked for problems and resoldered, by hand, if necessary.

Finished modules are X-rayed by this machine to check the module at the lowest level.

When a new batch of modules is developed, they go through stress testing in a heated environment. These machines run loops in a controlled environment of up to 75C, to make sure modules will run within operating specs.

Every single Corsair memory stick gets tested in a fully working machine.

The machines are based around popular platforms for that stick of memory - such as the Asus A7N8X, which uses PC3200 memory. The stress test is contained on this PCI card, which costs in the region of £500 just for a single one!

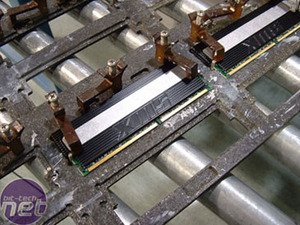

Once tested, the modules are ready to be heatsinked (heatsunk?)

The finished thing is clamped together ready to be packaged up.

Spot the quote?

That\'s a lot of memory!

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.